ABC’s of Manual Cleaning - Part III: How does Manual Cleaning Work?

In the third part of our six-part blog on cleaning, we're diving into a key question: how is manual cleaning typically carried out? A strong manual cleaning program is built on the combination of science and management to create effective Sanitation Standard Operating Procedures (SSOPs) that employees must fully understand and follow.

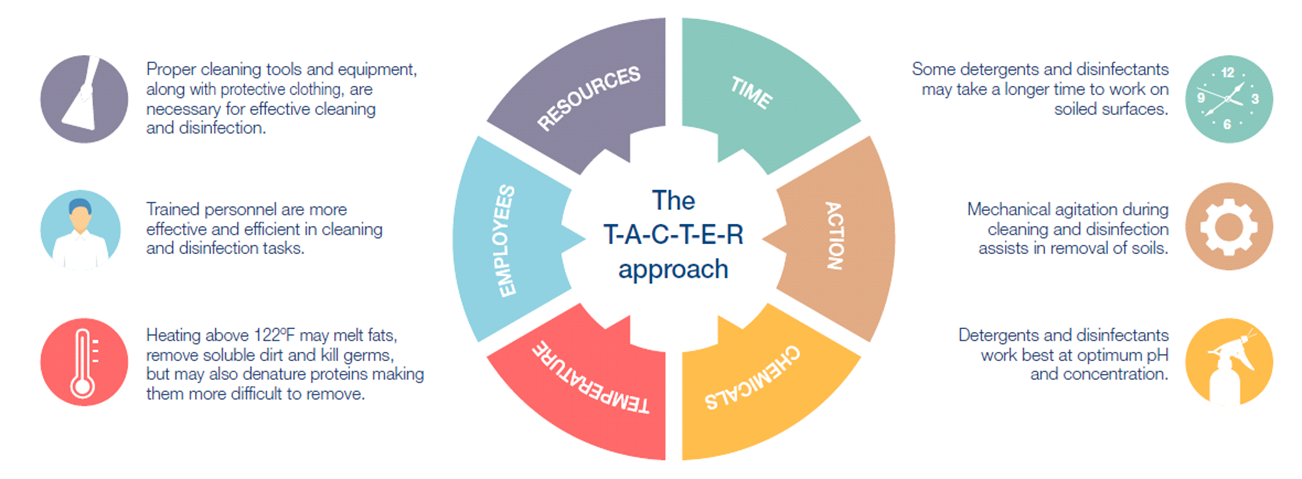

Assess the TACTER Parameters

The TACT model was developed by Dr. Herbert Sinner in 1960. We've expanded it with two additional factors—Employees and Resources—to create a more complete framework for effective cleaning.

If a surface has heavy contamination, the TACTER requirements become more demanding. For instance, workers may need to clean more thoroughly to remove all contaminants effectively.

Evaluate Cleaning Program Considerations

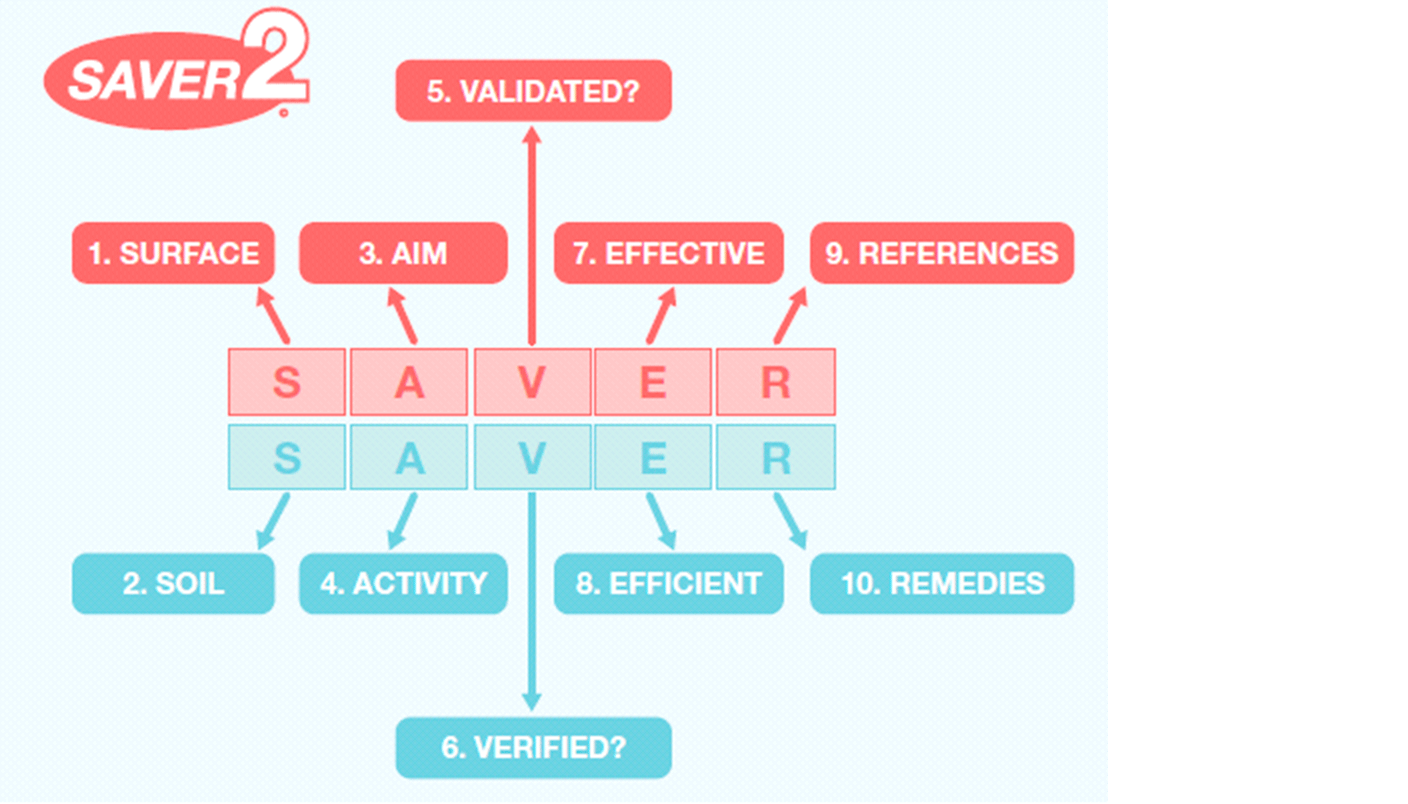

We’ve also introduced the SAVER2 model to help you build a comprehensive cleaning and sanitation program. It covers key aspects like:

This model considers:

- What type of Surface is being cleaned?

- What is the nature of the Soil being removed?

- What is the Aim of the cleaning process?

- What Activity is being performed step by step?

- Is the decontamination Validated?

- Is the process adequately Verified?

- How Effective is the activity?

- How Efficient is it?

- Are there valid scientific or technical References?

- Are Remedial actions in place to prevent issues?

Cleaning decisions should be risk-based

Depending on the type of soil, surface, and other factors, sites may choose dry-cleaning, wet-cleaning, or controlled wet-cleaning methods:

Dry-cleaning

Wet-cleaning

Controlled wet-cleaning

Dry-cleaning uses little or no water and is common in facilities handling low-water-activity products like flour or milk powder. This prevents microbial growth from water exposure. However, extra care is needed to avoid airborne allergens during dry cleaning.

Wet-cleaning uses water to remove soluble soils and is common for high-water-activity foods like meat or beverages. But it can lead to microbial growth and high water usage. Controlled wet-cleaning of small parts at remote stations helps reduce cross-contamination risks.

Document and implement steps clearly

Employees must be well-trained to carry out these tasks. Here are recommended steps for wet-cleaning:

- Secure equipment, disassemble, and dry-clean to remove large debris.

- Pre-rinse with potable water from top to bottom.

- Apply detergent and scrub from bottom to top.

- Post-rinse with potable water and self-inspect.

- Have QC perform a formal inspection.

- Disinfect, rinse, dry, and re-assemble equipment.

- Obtain supervisor verification before use.

- Adjust the order based on risk assessments.

Using the right tools and chemicals at correct concentrations is vital for effective cleaning.

Next Steps

In our next blog, we’ll cover how to determine the frequency and locations for manual cleaning. Stay tuned!

Selected References:

- Remco (2020). The Role of Manual Cleaning in Biofilm Prevention and Removal. https://go.remcoproducts.com/biofilms

- Smith, Debra (2017). Optimising Food Safety Through Good Cleaning Tool Maintenance. https://remcoproducts.com/cleaning-tool-maintenance/

Recent blog posts

ABC’s of Manual Cleaning - Part I: Why is it important?

This blog series explores the importance of manual cleaning in food safety and its role in safe production processes.

ABC’s of Manual Cleaning - Part II: What does Manual Cleaning Involve?

Manual cleaning is often the best option for complex equipment and critical areas where automation isn’t feasible.

ABC’s of Manual Cleaning Part IV: Where and When to Manual Clean?

Part four focuses on identifying high-risk areas and determining how frequently they need cleaning to maintain hygiene standards.

Recent blog posts

ABC’s of Manual Cleaning Part V: Who is Responsible for Manual Cleaning?

Part five highlights the departments involved in maintaining proper cleaning and sanitation practices within a food facility.

ABC’s of Manual Cleaning Part VI: Regulatory and Standards Expectations Regarding Manual Cleaning

This final post in the series covers EU and U.S. regulations, industry standards, and best practices for manual cleaning in food facilities.

Bedroom Furniture,Storage Furniture,Bedside Tables,Bedroom Accessories,night-tables

Foshan Jianermei Furniture Co., Ltd , https://www.minottiitaly.com