Controlling Cronobacter: A Pathogen of Concern in Dry Environments and Low-Moisture Foods

Cronobacter is a common bacterium found in the environment that can also survive in low-moisture foods. These include items like dried milk powder, herbal teas, and starches, which have a water activity (aw) level below 0.85. The presence of Cronobacter in such products poses a significant risk, especially in dry food production environments.

While infections caused by Cronobacter are rare in the general population, Cronobacter sakazakii (1) has been linked to several foodborne outbreaks. It is particularly dangerous for newborns, potentially causing severe infections such as septicemia, meningitis, and even death.

The U.S. Food and Drug Administration’s (FDA) Coordinated Outbreak Response and Evaluation (CORE) Network, in collaboration with the Centers for Disease Control and Prevention (CDC), recently investigated infant formula products. As part of this effort, four hospitalizations and two deaths were reported, with Cronobacter possibly contributing to both fatalities (2,3).

Cronobacter sakazakii: Key Information

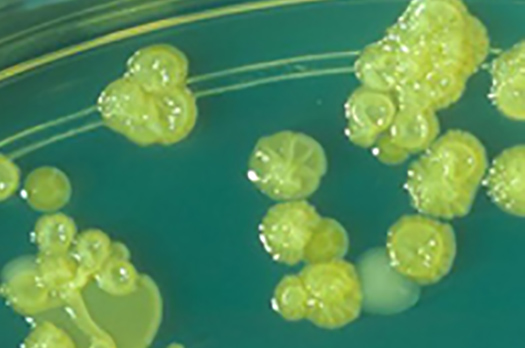

Cronobacter sakazakii

Source: FDA (1)

Characteristics: Gram-negative, non-spore forming bacteria commonly found in the environment.

High-Risk Areas: Survives in dry conditions and low-moisture foods like powdered infant formula for extended periods.

Affected Groups: Neonates, infants, elderly, and immunocompromised individuals. Mortality rates range from 10% to 80%.

Transmission: Most infections result from consuming contaminated food.

Symptoms: Jaundice, temperature fluctuations, grunting, seizures. Infants are at high risk for meningitis.

Infective Dose: Not clearly defined. Symptoms appear in infants within days or weeks, but onset in adults remains unclear.

Cronobacter: Control Measures

To reduce the risk of Cronobacter contamination in powdered infant formula and similar high-risk products, the following strategies are recommended:

(a) Ensuring proper process controls – Although Cronobacter can survive in low-moisture products for up to 2 years, it is easily eliminated by pasteurization, sterilization, or other thermal treatments. These steps must be scientifically validated to ensure effectiveness. Any ingredients added post-thermal treatment should be handled under strict hygiene protocols to prevent final product contamination.

(b) Providing clear consumer guidelines – Manufacturers should offer specific advice for preparing infant formula for babies under 2 months, preterm infants, or those with weakened immune systems. This includes following CDC recommendations, FDA guidelines, and WHO standards to minimize Cronobacter risks.

(c) Implementing environmental monitoring programs – Experts recommend routine testing of surfaces in low-moisture food facilities for indicators like Enterobacteriaceae. A positive result may suggest the presence of Cronobacter, which can then be confirmed through targeted pathogen testing. This helps identify contamination hotspots and allows for improved sanitation practices.

(d) Controlling post-processing contamination – Facilities should minimize water use during cleaning, as water can promote bacterial growth. Using dry sanitation tools and methods is crucial to reducing microbial risks effectively.

(e) Developing a comprehensive sanitation program – Vikan and Remco recommend an integrated approach to sanitation, including risk-based hygienic zoning, color-coded tools, hygienically designed equipment, and regular decontamination and maintenance of tools.

Vikan has been supporting dry production and hygiene-sensitive industries for nearly 125 years with high-quality sanitation tools and innovative solutions. For more information, visit our website or contact us for a free site assessment.

References:

1. Bad Bug Book (Second Edition) | FDA

2. Home | Cronobacter | CDC

3. FDA Investigation of Cronobacter Infections: Powdered Infant Formula (February 2022) | FDA

4. Dry Snacks Ready-To-Eat Processing - Remco (remcoproducts.com)

5. https://viewer.ipaper.io/vikan/white-papers/5s-in-the-food-industry/5sfoodindustryen/

6. http://viewer.ipaper.io/vikan/food-safety-information/ultra-hygiene/ultra-hygiene-advertorial-en-300/

7. How to Keep Cleaning Tools from Becoming Vectors of Contamination (vikan.com)

8. Cleaning-Tool-Maintenance-WhitePaper-EN-300 (ipaper.io)

9. Bourdichon, F., Betts, R., Dufour, C., Fanning, S., Farber, J., McClure, P., & Winkler, A. (2021). Processing environment monitoring in low moisture food production facilities: Are we looking for the right microorganisms? International Journal of Food Microbiology, 356, 109351.

Recent blog posts

IAFP 2022 Focused on Food Safety in the City of Bridges

Pittsburgh, Pennsylvania, the U.S. Steel City, hosted the IAFP 2022 Conference from July 31st to August 3rd. Around 3,000 food safety professionals from across the globe, representing regulatory, academic, and industry sectors, gathered to discuss the latest advancements in food safety science and practice.

USDA Unveils Food Systems Transformation Framework to Balance Efficiency with Resiliency

U.S. Secretary of Agriculture Tom Vilsack announced the USDA’s new comprehensive framework in early June 2022. The framework aims to strengthen the food supply chain and transform food systems to better serve consumers, farmers, and communities while promoting sustainability and resilience.

New Era of Smarter Food Safety Begins 2022 with New Projects

The FDA emphasizes the importance of food safety culture and the Foodborne Outbreak Response Improvement Plan, highlighting the need for continuous improvement in how food safety issues are managed and resolved.

Guangzhou Liben Plastic Industry Co., LTD , https://www.libenbaby.com